What Is The Mes/Oee Operator?

Operator MES is a manufacturing efficiency metric. It is also called Overall Equipment Effectiveness, and it is calculated by dividing the SUM of the machine downtime by the SUM of machine hours. This article will give an overview read more about MES and MOM of what Operator MES or OEE means in terms of manufacturing, provide mathematical formulas for calculating it, and provide an in-depth example to better illustrate how to calculate this metric.

Operator MES is the output of machine utilization. It is the desired output of an operator, which depends on how effective they are at what they do. If an operator is good at making every part they handle, that machine will realize an OEE of 100%. If it takes those 20 seconds to make a part and it takes those 30 seconds to make another part, but theirs generates a lot of waste and time because it’s not as efficient as the first one, then their OEE would be below.

Operators can also monitor and learn from their work and improve or even lower their OEE by working smarter and more efficiently. Like the machine, operators can also work smarter and more efficiently to realize an OEE of 100%.

How Can You Improve Your Overall Efficiency (OEE) Monitoring?

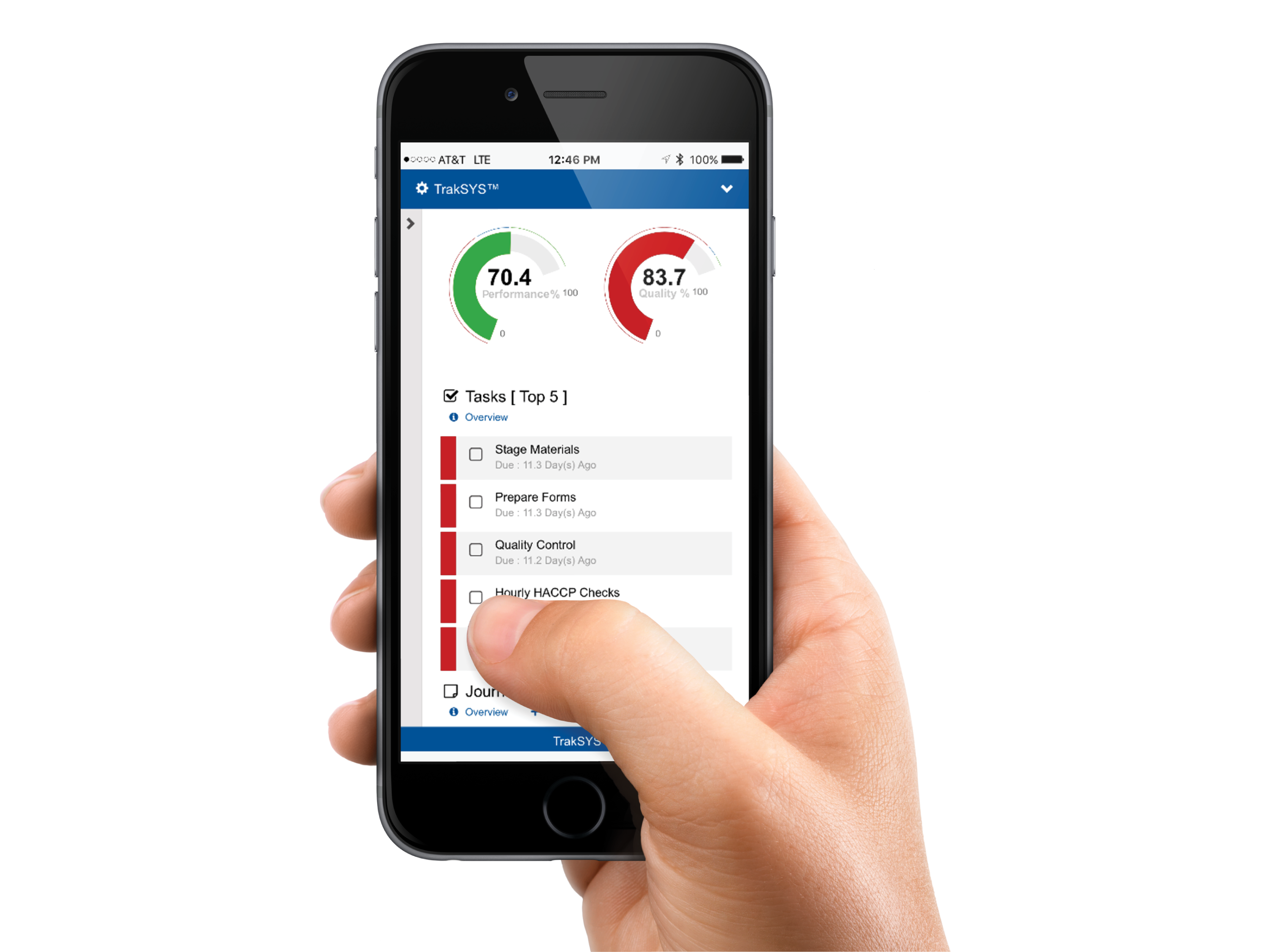

Every day, production managers must make decisions that impact the overall productivity and quality of their operations. With an ever-increasing percentage of capital invested in production equipment and facilities, it’s more important than ever to make the right choice at the time.

Read on for the different OEE measurement tools you can use to help you make the right decisions in your production processes.

Remote Monitoring As An Alternative To OEE Metrics

You may have heard about the ‘remote monitoring’ of industrial machinery. Remote monitoring involves accessing data remotely via a network. This means you don’t need to be physically present to collect data or change settings. This is useful for when you need to remotely maintain your equipment or when it’s difficult to access it in person, such as when equipment is located outdoors, at great heights, or outdoors in cold weather. In addition, remote monitoring allows production managers to gather data more easily and at a higher frequency due to its convenience and accessibility.

Remote monitoring software is available in various formats, including cloud-based applications that can be accessed on any computer or device connected to the internet. In addition, cloud-based software offers the bonus of sharing your data with other users, including other equipment managers, maintenance technicians, and suppliers.

Are Accelerometers Able To Be Used For OEE Measurement?

Accelerometers are devices that can measure vibrations in the workplace. While their primary use is for eliminating faults within production machinery, they can also be used for OEE measurement by combining vibration with location data.

One of the most common ways to measure vibration is with an accelerometer, which is a device that detects vibration. The use of accelerometers for OEE measurement is not new; these devices have been used for several industries, including the automotive industry, for decades.

Accelerometers measure vibration by converting movement into electrical signals that are then detected by the Numa-meter chip. The numa-meter, or ‘numerical amplifier,’ converts signals into digital numbers displayed on the monitor. The numa-meter chip also shows movement in real-time via picture images.